The production of oil and gas wells has been affected by different problems resulting in production losses and irreversible deterioration of equipment. Many chemical products called “additives” are injected into the wells in a continuous way to prevent and control these problems ( incrustrations, corrosion, paraffin) so as to keep the well “inhibited”.

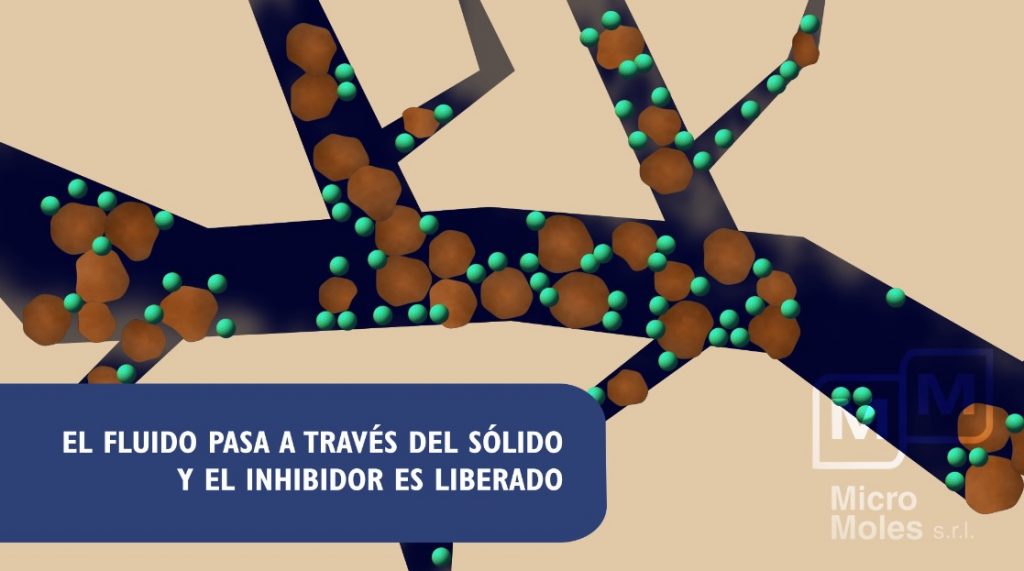

The microencapsulated solid inhibitors are made up of carrier spheres, especially developed with porosity and permeability characteristics, that contain an inhibiting active ingredient inside them. These inhibitors are free flow spheres, without any apparent liquid properties. The inhibitor is released from the sphere slowly, when it is immersed in a liquid medium.

The conformation and micro-structure of these materials provide them with the same or better instantaneous performance than the homologous liquid product. Besides, long-term residual action is added, without any need to replace the product as in the case of the liquid. Controlled release is added too, by which the released chemical is the required one for the problem to be treated.

As the well production fluid passes through the solid, the inhibitor is released, and the chemical flows inhibiting the formation against parafins, incrustrations, corrosion, bacteria, etc. The well production is the one to determine the amount of released chemical. Only a small amount of chemical is necessary for the inhibition and this optimizes its efficiency. Several of these treatments have provided greater inhibition time, even in wells where problems have been observed historically. That is why the solid inhibitors have become an accepted and required procedure in several terminations.

THE FLUID GOES THROUGH THE SOLID AND THE INHIBITOR IS RELEASED

APPLICATION FORMS

- Production : The solid inhibitor is placed in the rathole (downhole), from where the product will act releasing the active ingredient.

- Fracture : It is the most suitable moment for the treatment to be applied, as the inhibition starts at the very moment the well is put into production. The selection in size and shape allows the solids to be applied together with the support agent (proppant) and are easily incorporated in the fracture works.

Advantages and Benefits

- Instantaneous action when coming into contact with the liquid system, added to a long-term residual action : more than one-year protection in only one application.

- The necessity to replace the product continuously ( liquid inhibitors) is avoided.

- Controlled release : The released chemical is the required one for the problem to be treated. A significant lower amount of chemicals is applied, due to the

focused action and gradual release inside the well.

- Possibility of mixing several solid inhibitors to tackle various problems in only one application.

- Application in both fracture treatments (mixed with the support agent Proppant) and production (dosage in rathole).

- Lower comparative cost: chemicals, maintenance and labour work. Higher performance over the dose (ppm) used. And lower transport cost.

- Possibility of changing the size and type of the carrier particle to suit each application and specific requirement.

- Solid products easy to handle, store and clean; there are no liquid spills.

- Environmental : The spills are easily cleaned. The amount of chemical sent to the formation is far lower than in the case of the liquids.

- For the worker: There is no risk of skin, eyes, nose contact with dangerous liquids. Lower quantities of the product, less physical effort. Emissions and vapours reduction.

Micromoles is an Argentine company producer of chemical solutions focused on the Oil &Gas segment. Produce, represent and distribute top-level international chemical products. Have a new plant for the manufacture of chemical and microencapsulated additives.

From the very beginning, Micromoles’ aim has been to provide the best products and services, keeping their clients updated on technical and commercial news about the products they work with.

The main aim of the constant search and incorporation of new representations and technology has always been the diversification and improvement of the offer of products and solutions for clients.

MICROMOLES s.r.l.

Web : www.micromoles.com.ar

Mail: info@micromoles.com.ar

Dirección: Mercedes 3951 -2º B