Very few environments are as demanding as those on an oil rig. Materials are stressed and corrosion is promoted by water, salt and wind, as well as extreme weather fluctuation. The highly innovative Festo Motion Terminal as well as the state of the art valve terminal VTUG combined with our control cabinets offer reliable and steady solutions for automation of fingerboards under these harsh conditions

Safe even under extreme ambient conditions

At a height of greater than 60 ft, pneumatically operated fingers secure lengths of tubular pipe which are not required at the moment. Corrosion-resistant equipment is required to this end which functions reliably when placing drill pipes into and removing them from the racks, is easy to maintain and ideally doesn’t have to be repaired at all.

Innovative or traditional: pneumatic alternatives

With the new app-controlled Festo Motion Terminal VTEM position sensing is made possible on the fingerboards only via pneumatic tubing – without any electronics at the latch or on the actuator. And the new VTUG, optimised for use in the control cabinet and with numerous explosion protection certifications, replaces explosion protected control cabinet solutions. With its bulkhead interface it can be easily mounted directly to the cabinet wall. In that way tubing connections in the control cabinet are a thing of the past. Other stainless steel components from Festo are a perfect match for this automation solution.

Highlights

- Safe even under extreme ambient conditions

- Sensing without electronics at latch

- Reliable operation

- Easy to maintain and repair

- Explosion protection

- Resistant to corrosión

- Innovative or traditional solution

- Air leakage detection for safety and eficiency

Highly innovative: Digitised fingerboard control with the Festo Motion Terminal

A single piece of hardware for many functions

Pneumatics is a simple technology often used for the control of fingerboards in Oil & Gas. The Festo Motion Terminal VTEM now makes this simpler, more versatile, safer and more reliable – moving pneumatics into the age of Industry 4.0. The VTEM is an innovation that utilizes Motion Apps to define valve functions.These apps allow a traditional pneumatic valve to now have proportional, control, feedback and energy conservation elements. Functions can be changed at the push of a button without changing the hardware. The Festo Motion Terminal combines a smartphone-like easy-to-use approach with a lot of technological benefits and exclusive product features:

- Security against manipulation

- Protection of intellectual property

- Condition monitoring

- Self-regulation

- Simple operation

- Increased energy eficiency

End position detection:

Open, close or failure signals without electrical limit switches. With VTEM a single valve slice can replace the traditional solenoid valves and sensors on two fingerboard actuators. By monitoring and modeling air flow, the VTEM accurately reports if the latch is opened, closed or blocked. By moving from traditional sensors to the VTEM, you can save costs for components on the rig and reduce service time and risk, while gaining new critical information.

Benefits with VTEM:

- No electrical components on the fingers

- No electrical wiring to fingerboard

- Reduced effort for installation and wiring

- Reduced effort for maintenance directly at the finger

- Reduced risk for maintenance workers

- Reliable information if finger is opened/closed/blocked

- Detection of tube leakage

- Improved diagnostics and quick failure detection

Available Motion Apps

Operate finger and get feedback on the position simply via pneumatic connection.

Leakage diagnostics Fewer system downtimes and faster fault detection due to preventive maintenance. Separate diagnostic cycles and defined threshold values enable you to detect and localise individual leaks in the application operated by the Festo Motion Terminal.

Selectable pressure level Save energy by setting several pressure levels. Simply set the pressure for the selected movements to a level of your choice. Additionally, you can control the speed by adjusting the flow control valve setting.

Supply and exhaust air flow control. Do away with separate flow control valves on the actuator and set tamper-proof travel speeds quickly and conveniently at the touch of a button. There is also an option to implement new motion sequences such as dynamic flow control adjustment.

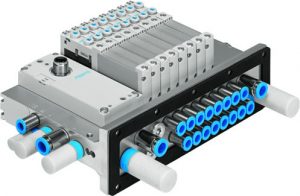

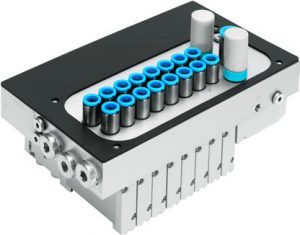

Optimized state of the art: Fingerboard control with VTUG

A wide range of functions and details, such as pneumatic connections underneath, make the VTUG with plug-in particularly suitable as a reliable valve terminal for installation in control cabinets. VTUG has many multi- pin variants and a very simple connection for all standard field- buses and IO-Link®. It is also quick to install and configure, and is particularly suitable for control cabinet installation. Best for OEMs and all those who appreciate high pneumatic functionality and electric modularity. Control cabinet seals are suitable for IP69K / NEMA4X applications.

Small, fast, energy saving: VTUG for control cabinet use

VTUG can be easily mounted inside a cabinet on the wall with a bulkhead interface and maintain all cabinet approvals. The result is a smaller cabinet, less leakage points and quicker fabrication time. You decide whether the VTUG is installed in a horizontal or vertical way.

Features for increased resistance and robustness

- Very reliable: the new check valves

- No more problems with back pressure

- Installed directly in the ducts of the manifold rail

Fixed restrictors: for individual, low-cost and reliable speed control

- Various nominal sizes

- Tamper-proof speed control

- Installed directly in the ducts of the manifold rail

High corrosion resistance: stainless steel coating for manifold rails

- For 4, 8, 12, 16 and 24 valve positions

- Standard variant already offers IP69K

- Optional: stainless steel

- coating for increased corrosion protection

Technical highlights

- Optimized for enclosure installation (horizontal/ vertical)

- Sizes 10 and 14

- Pressure range up to 10 bars

- Parallel use of vacuum and pressure on one valve terminal / manifold

- Flowrates up to 630 l/min

- Up to 24 valves on a single terminal

- Hot Swap function for valve replacement during operation without depressurizing the valve terminal

- Fixed, tamper proof restrictors: for individual and reliable speed control

- Certifications (IECEx, ATEX 3G)

- Protection class IP67, in enclosure IP69K, NEMA 4X

- Various fieldbus protocols: PROFInet, PROFIBUS, etc.

- Proven in use valve technology

What else do you need for the automation of fingerboards?

These components expand the VTEM and the VTUG for the best. And you get top quality from a single source as a result. With the help of these solutions, your fingerboards work safely, reliably and lastingly at a favourable price.

Linear actuator

- Stainless steel design

- Coated spring

- Characteristics specifically adapted to your application

Air preparation units

- MS series: One for all, complete product family, individual configurations, safety functions, high flow rates, Ex certificates.

- PCRP: Corrosion resistant stainless steel version.

- D-series: sturdy full metal design.

Fittings and tubings

- Various tubings with high weather and corrosion resistance

- Stainless steel fittings

Supply complete control cabinets

The made-to-measure control cabinets are individually designed and built for applications with specific industry requirements. The design is also influenced by local conditions such as weather and climate. Along with Festo components, third-party components are integrated into the control cabinets as required. Enclosures for hazardous locations are built in our own UL certified panel workshop. The operationally tested system is delivered ready- to-install.

Automation platform CPX

CPX is ideal as an automation platform, valve terminal partner or remote I/O – it is electric, open and direct. It is also the perfect platform for electrical peripherals. With CPX, you can integrate pneumatic and electrical control chains easily, quickly, flexible and seamlessly into all automation concepts and company-specific standards – and into Industry 4.0 as well! Addionally CPX offers comprehensive diagnostics and condition monitoring functions, also via IoT gateway and Festo Cloud.